Solar Materials

Backsheet

Backsheet maintains the highest efficiency of

Backsheet maintains the highest efficiency of

solar modules with perfect electrical insulation and excellent durability.

Product Info.

-

Various Film

Processing

Technology -

Differentiation of Material

Application of

Materials with

Long-term Reliability -

Various Products Line Up

High-functional

Product Family

- It is attached to the back of a solar cell module to prevent penetration of water, shock and UV rays, and protects the cell and module.

- For long-term durability, film processing technology such as coating/lamination and coextrusion is applied by using fluoric film, weather-resistant PET, and weather-resistant polyolefin film.

Application

Type

HBS-P Series (PET Type)

- Feature

-

- Excellent Solar Reflectance achieved through bright white film

- Outstanding Stability shown in DHT, HAST

- Superb bond strength to EVA sheet

- Type

-

- 1,000V (White/Black/Transparent)

- 1,500V (White/Black/Transparent)

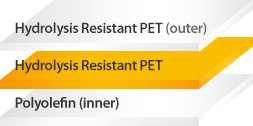

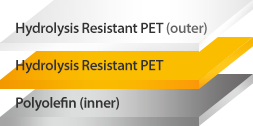

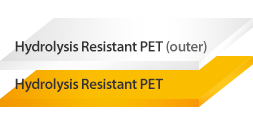

- Structure

-

-

<White>

-

<Black>

-

<Transparent>

Hydrolysis Resistance PET The special-processed Hydrolysis Resistance PET has better weatherability compared to the general PET and protects the module from extreme weather conditions

-

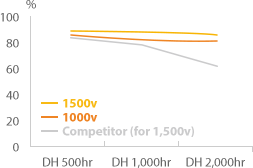

- Strengths

-

- Good reflectivity

- Durability for UV & damp heat

-

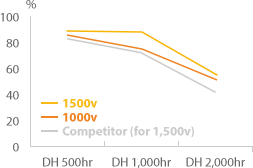

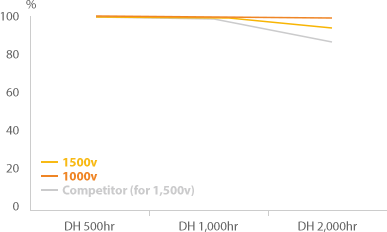

Retention ratio(%) of

Tensile Strength after DH

-

Retention ratio(%) of

Elongation at break after DH

-

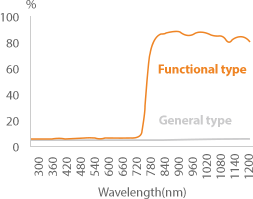

Reflectance (%)

HBS-S Series (Fluorinated Type)

- Feature

-

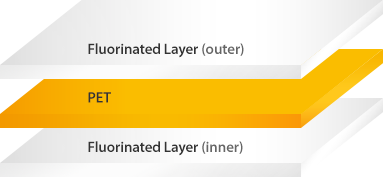

- Excellent UV resistance and weatherability

- Consistent electrical insulation under high voltage

- Superb bond strength to EVA sheet

- Type

-

- 1,000V (White/Black/Transparent)

- 1,500V (White/Black/Transparent)

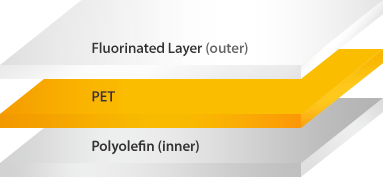

- Structure

-

- Strengths

-

- Superior reliability against UV stress

- Good reliability against severe climate

-

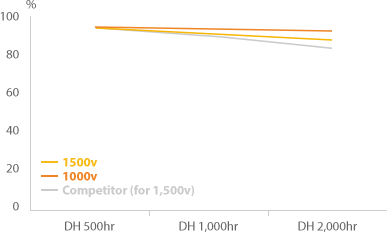

Retention ratio(%) of Tensile Strength after DH

-

Retention ratio(%) of Elongation at break after DH

HBS-D Series

- Feature

-

- Excellent solar reflectance achieved through double-sided fluorinated coating

- Type

-

- 1,000V (White/Black/Transparent)

- 1,500V (White/Black/Transparent)

- Structure

-

HBS-X Series

- Feature

-

- Non-aluminum low WVTR (<1.5g/㎡·day) Backsheet

- Type

-

- 1,000V (White/Black/Transparent)

- Structure

-

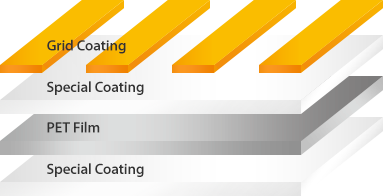

Grid Type Backsheets

- Feature

-

- Black / White grid coating can be applied based on customer’s cell shape and size

- Good UV resistance and Weatherability

- Type

-

- 1,000V, 1500V (HBS- P, S, D, X Series)

- Structure

-

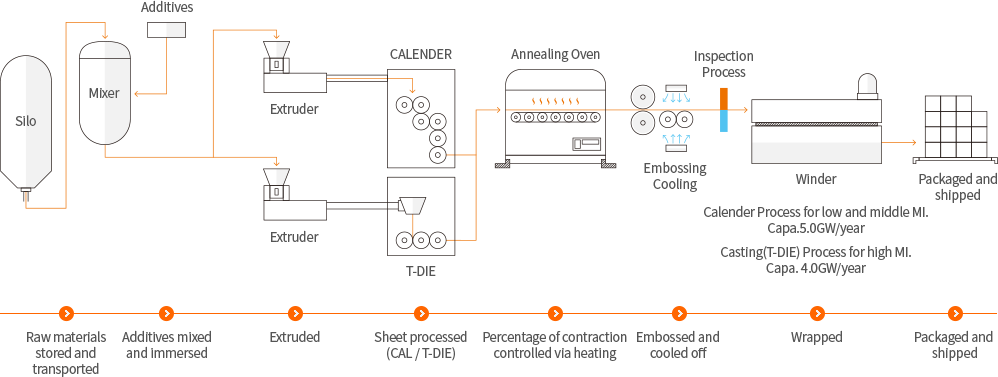

Production Process

Material Process

Inquiries

Solar Materials

- kis8park@hanwha.com